Reducing soft plastic waste through innovation

Building, Construction, Design, Engineering, Sponsored Content

Building, Construction, Design, Engineering, Sponsored Content

This is a sponsored article from SustainabilityTracker.com member SVC Products Pty Ltd.

Amid the recent failure of Australia’s RedCycle soft plastics recycling program, addressing the problem of soft plastics has become increasingly crucial. To tackle this issue, SVC Products, a prominent Melbourne-based producer of customised precast concrete items, is contributing by diverting soft plastic waste out of landfill, using it in the form of recycled plastic aggregate within its concrete products. This initiative has led to promising projects.

Concrete products are made from a combination of cement, water and aggregate material. The most common aggregates used in concrete are gravel, sand and crushed rock. Their presence within a concrete mix is necessary for the concrete to achieve its required strength properties. Aggregates are sourced from local stone suppliers, who mine the raw stone material from quarries. As concrete production surges, so too does the demand for aggregate material, leading to the depletion of finite natural resources. SVC have explored what other materials can be used as substitutes for natural stone aggregates.

What other materials can be used as substitutes for natural stone aggregates? One answer is somewhat unexpected, but works: recycled soft plastics.

SVC has established a partnership with the team behind Polyrok, a product that provides a sustainable, environmentally friendly replacement for mineral aggregates. Born from the compelling need to find a solution for problematic soft plastic waste, Polyrok is an innovative, functional product that contributes to a circular economy.

Polyrok is made using post-consumer grade soft plastic waste, collected by Cleanaway. It has the potential to become a large-scale solution for the safe disposal of harmful soft plastics, while simultaneously reducing the construction industry’s reliance on stone aggregates.

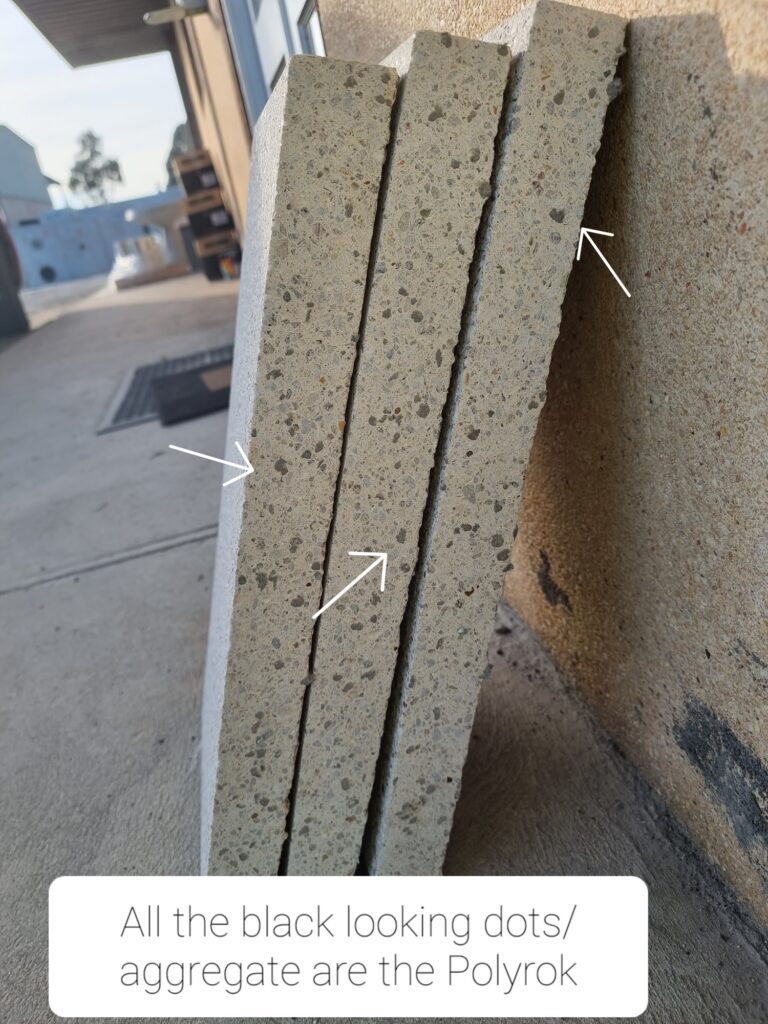

Compared to traditional stone aggregates, Polyrok is lighter, more thermally efficient, and easier to transport. Made from everyday waste items such as cling wrap, plastic bags and food wrappers, Polyrok’s final form is a twisted, rock-like shape which bonds extremely well to concrete.

Recycling soft plastics is a challenging task due to the high levels of contamination and inadequate recycling facilities. Consequently, most soft plastics end up in landfills or the ocean, where they can release harmful toxins into the environment as they break down. The conversion of soft plastic waste into recycled plastic aggregate offers a promising solution.

When Polyrok is used within concrete, it is locked away from the natural environment, tightly bound in its concrete enclosure, and doesn’t degrade. Furthermore, when the concrete product reaches the end of its lifespan and is crushed for recycling purposes, the Polyrok aggregate can be easily extracted from the concrete for reuse.

SVC is an early adopter of Polyrok, and is fully supportive of its uptake within the manufacturing and construction industries. To incorporate Polyrok into its own manufacturing processes, SVC has invested in operational upgrades and internal product trials to ensure successful integration. The company is now deploying Polyrok on a regular basis, while also reducing its consumption of stone aggregates.

Hundreds of concrete products across SVC’s broad range of Civil product solutions now contain a percentage of recycled soft plastics. These products are distributed across Victoria for use in council works, major projects and infrastructure programs, allowing these projects to achieve sustainability targets through material procurement.

Based on SVC’s current consumption of Polyrok, the numbers are impressive. Allowing a conservative estimate of 1.5 tonnes of Polyrok used per week at SVC, this translates to 72 tonnes of Polyrok per year, or a diversion of 18 million pieces of soft plastic away from landfill.

This is an article from a SustainabilityTracker.com Member. The views and opinions we express here don’t necessarily reflect our organisation.